| Mosin Nagant Rifle Bore Slugging Tutorial All content copyright © 7.62x54r.net |

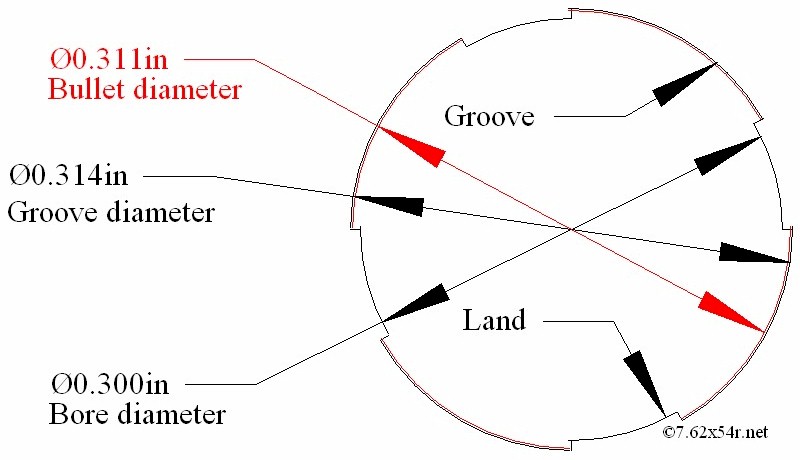

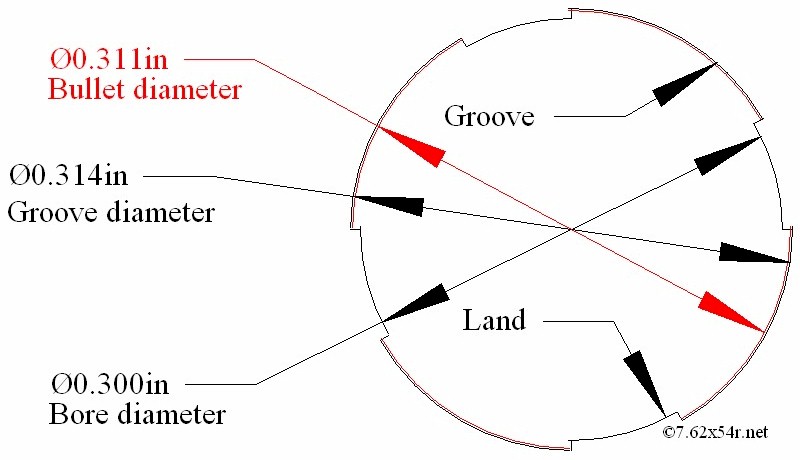

A common question asked by Mosin Nagant collectors is "How do I tell what size bore my rifle has?" In this context the term "bore" is referring to the inside of the barrel in general and is not interchangeable with bore diameter. This may sound confusing at first, but it must be understood that the inside of the barrel has two different dimensions measured at the lands and the grooves. The lands are the high parts that impart spin to the bullet and the distance between them is the bore diameter. The grooves are the low parts between the lands and the distance between them is groove diameter. All models of Mosin Nagant rifles have a nominal bore diameter of .300" or 7.62mm. Although bore diameter will vary somewhat, it is usually not a concern unless the bore is extremely worn. What is important in bullet selection is the groove diameter. A bullet larger than the groove diameter can cause dangerously high pressure when the rifle is fired. A bullet significantly smaller than the groove diameter might not stabilize properly and be inaccurate. Ideally the bullet should be slightly smaller than the groove diameter. Because of the wide variation in groove diameter between models and even within models the only way to be sure is to slug the "bore", or inside of the barrel. The result is a good first step in determining what ammunition or size of bullet for handloading will be most accurate in a specific rifle. The process is not difficult and requires a minimum of investment in tools, materials and time. See the picture below for an illustration of the realtionship between the lands, the grooves, and the bullet.

Tools and Materials While there are commercial bore slugging kits available from gunsmith suppliers, I have put together a kit with inexpensive and readily available materials. These include 1/8 size "egg sinker" fishing weights available at WalMart, a 1/4" diameter wooden dowel from Home Depot (or WalMart), a small piece of wire I had in the shop, some gun grease (any type of thick lubricant would work), a plastic mallet, a shop towel, and a caliper for measuring the slug. The dowel is cut up into approximately 6" sections. The number required depends on the length of the barrel. The caliper is by far the most expensive item at about $25-$30. I purchased mine from MidwayUSA, but have since seen them in the tool department of Home Depot. The total kit should cost no more than about $50. For rifles of larger or smaller caliber an adjustment would need to be made in the size of the lead slugs and possibly the dowel. It has been suggested that 00 buck shot will work as a slug, but I have not tried it and like the hole through the middle of the sinker for reasons that will be obvious.

The Process For larger views, click on the pictures.

| Before beginning any disassembly, maintenance, or cleaning on any firearm visually inspect the chamber and magazine to be sure that it is unloaded. |

| All content copyright © 7.62x54r.net |